Introduction

Nitinol is a special metal made of nickel and titanium. It is known for its amazing properties of shape memory and superelasticity. These features have made it popular in many industries. This article will explain the types, features, and various uses of Nitinol, helping you understand this incredible material better.

Types of Nitinol

Nitinol can be classified into two main types based on its transformation temperatures and uses:

- Superelastic Nitinol:

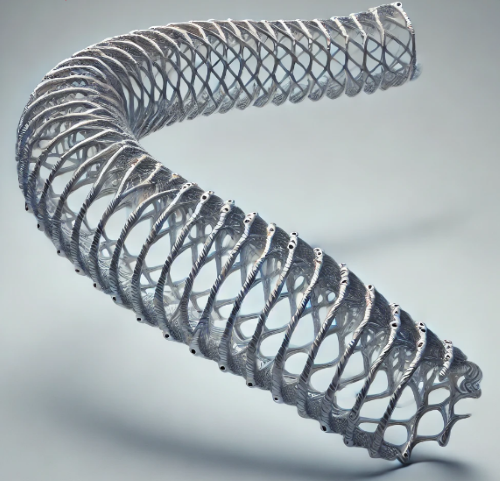

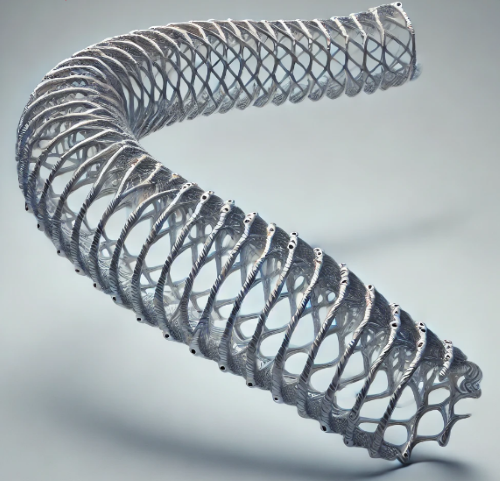

This type shows superelasticity at body or room temperature. It can bend and twist significantly and then return to its original shape without any damage. This makes it perfect for medical devices like stents and orthodontic wires that need to be flexible and durable.

- Shape Memory Nitinol:

This type can remember and return to its original shape when heated above a certain temperature. The temperature at which it changes can be controlled by adjusting the nickel-titanium ratio. It is used in devices like actuators, temperature control systems, and various consumer products that need a specific shape change when heated.

Features of Nitinol

Nitinol has several key features that make it useful in many applications:

- Shape Memory Effect (SME):

Nitinol can revert to a predetermined shape when heated above a certain temperature. This is very useful in the medical field for devices that need to be delivered in a compact form and then expand to their functional shape inside the body, like stents and other implants.

- Superelasticity:

Nitinol can undergo a lot of bending and twisting at a constant temperature and then return to its original shape when the force is removed. This gives it great flexibility and durability, making it ideal for products like orthodontic wires and eyeglass frames that need to bend and flex repeatedly.

- Biocompatibility:

Nitinol is non-toxic and works well with biological tissues. This is crucial for medical implants and devices that come into contact with human tissue, ensuring they are safe and effective, such as cardiovascular stents and surgical instruments.

- Corrosion Resistance:

Nitinol can resist corrosion in various environments, including bodily fluids and marine conditions. This makes it suitable for long-term use in harsh conditions, extending the lifespan and reliability of Nitinol products like medical implants and marine applications.

Related reading: Nitinol – Amazing Shape Memory Alloy

Uses of Nitinol

Nitinol’s unique properties have led to its use in many industries:

1. Medical Devices:

– Stents: Used to keep blood vessels open in cardiovascular procedures. They can be delivered in a compact form and then expand at the target site.

– Orthodontic Archwires: Used in braces to move teeth into the desired position gradually.

– Surgical Instruments: Their flexibility and strength make them perfect for minimally invasive surgical tools, improving precision and reducing patient recovery time.

2. Aerospace and Defense:

– Actuators: Used in aerospace applications to change shape in response to temperature changes, providing precise control for various systems.

– Vibration Dampers: Reduce vibrations in aerospace components, improving performance and longevity.

3. Consumer Electronics:

– Flexible Eyeglass Frames: Can bend significantly and return to their original shape, offering durability and comfort.

– Mobile Phone Components: Enhance the durability and performance of smartphones and other electronic devices.

4. Robotics:

– Artificial Muscles: Mimic muscle movements, providing flexibility and strength for advanced robotic functions.

– Microactuators: Essential for small-scale robotic applications, improving efficiency and accuracy.

5. Automotive Industry:

– Temperature Control Systems: Ensure reliable and precise temperature regulation using shape memory properties.

– Safety Devices: Enhance vehicle safety and performance by being incorporated into various safety devices.

Related case: Successful Case of Nitinol Wire Used in Medical Devices

Conclusion

Nitinol‘s extraordinary properties of shape memory and superelasticity, combined with its biocompatibility and corrosion resistance, make it a versatile and invaluable material across many industries. From medical devices and aerospace applications to consumer electronics and robotics, Nitinol continues to revolutionize the design and use of advanced materials.

As research and development progress, the potential uses of this shape memory alloy will continue to grow. For more information, please check Advanced Refractory Metals (ARM).